QA/QC Documents Essential to Construction Quality Management

4 Ekim 2024

0 Comments

Here, we delve into essential QA/QC documents that form the foundation of quality management in construction, ensuring every phase—from planning to project handover—meets stringent standards of quality, compliance, and efficiency.

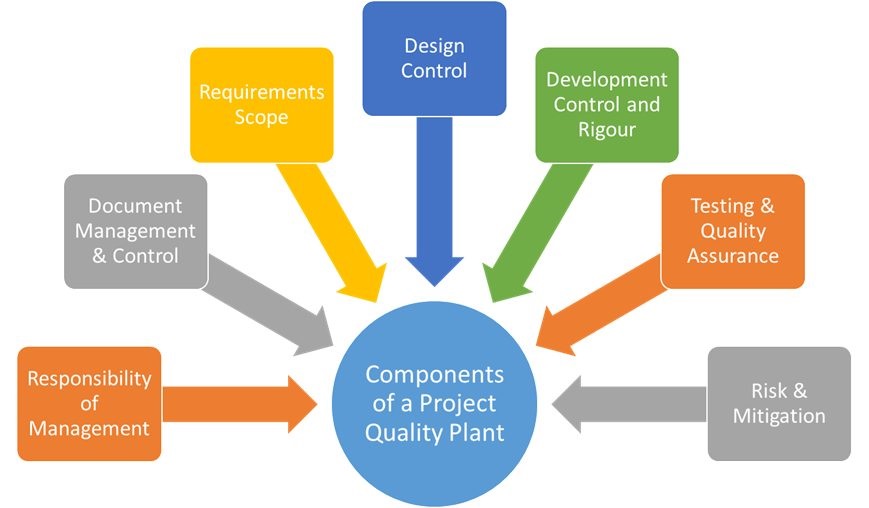

- Project Quality Plan (PQP)

Defines the project’s approach to quality management, detailing responsibilities and QA/QC procedures that align with ISO 9001:2015 standards. - Inspection and Test Plan (ITP)

Provides an outline of inspection and testing activities, listing inspection&test points, reference standards, acceptance criteria, and types of inspection levels such as Hold, Review, Witness, and Surveillance points. - Inspection Checklist

Used to verify that each construction activity meets quality requirements, often integrated into the ITP for ease of reference and tracking. - Prequalification Documents (PQD)

Specifies the requirements and standards that vendors or suppliers must meet to be considered for project participation. - Material Submittals (MAT)

Formal requests for material approval, ensuring that the selected materials align with project specifications and standards. - Non-Conformance Report (NCR)

Documents any deviation from project specifications and provides a plan for corrective actions to bring the work in compliance. - Corrective Action Report (CAR) / Corrective and Preventive Action (CAPA)

Details corrective actions to address non-conformance issues, and includes preventive actions to avoid future occurrences. - Request for Information (RFI)

A formal request submitted to resolve ambiguities or obtain clarifications on technical details within project documents. - Test Reports

These certify that materials, like concrete or steel, meet required specifications based on conducted tests. - Work Inspection Request (WIR)

Requests inspection of completed work, verifying that it meets standards before moving to the next construction phase. - Material Inspection Request (MIR)

Ensures materials delivered to the site meet project standards through an inspection process. - Shop Drawings

Shop drawings are produced by contractors and suppliers under their contract with the owner. The shop drawing is the manufacturer’s or the contractor’s drawn version of information shown in the construction documents. The shop drawing normally shows more detail than the construction documents. - As-Built Drawings

As-built drawings (also referred to as red-line drawings or as-builts) are revised sets of drawings submitted by a contractor upon the completion of the project. - Redline Drawings

Marked-up versions of drawings, indicating revisions, corrections, and modifications with clear annotations, typically in red ink. - Work Permit

A safety measure that authorizes specific construction activities under controlled and compliant conditions. - Snag List / Punch List

A checklist of items (defects or incomplete work) to be corrected or completed before the final project handover. - Final Handover Certificate

The conclusive document affirming that all contract and QA/QC requirements are met, signifying project completion.

These documents serve as the backbone of QA/QC processes in construction, ensuring quality, compliance, and efficiency from planning through to project handover.