Lean Construction: Building Smarter, Not Just Harder

In the construction industry, time is money, and delays can eat away at profits faster than a termite through a piece of wood. The old adage of “Cost + Desired Profit Rate = Price of the Product” no longer applies in today’s competitive market. Instead, companies need to work smarter, not just harder, to deliver projects on time, within budget, and with superior quality. This is where Lean Construction comes in.

Lean Manufacturing’s Impact:

Lean principles originated in the manufacturing sector, where the market dictates the price of a product. Companies had to adapt their approach, focusing on reducing waste (time, materials, defects etc.) to maximize value for the customer while achieving their desired profit margin. This translates to:

Profit Rate = Price – Cost

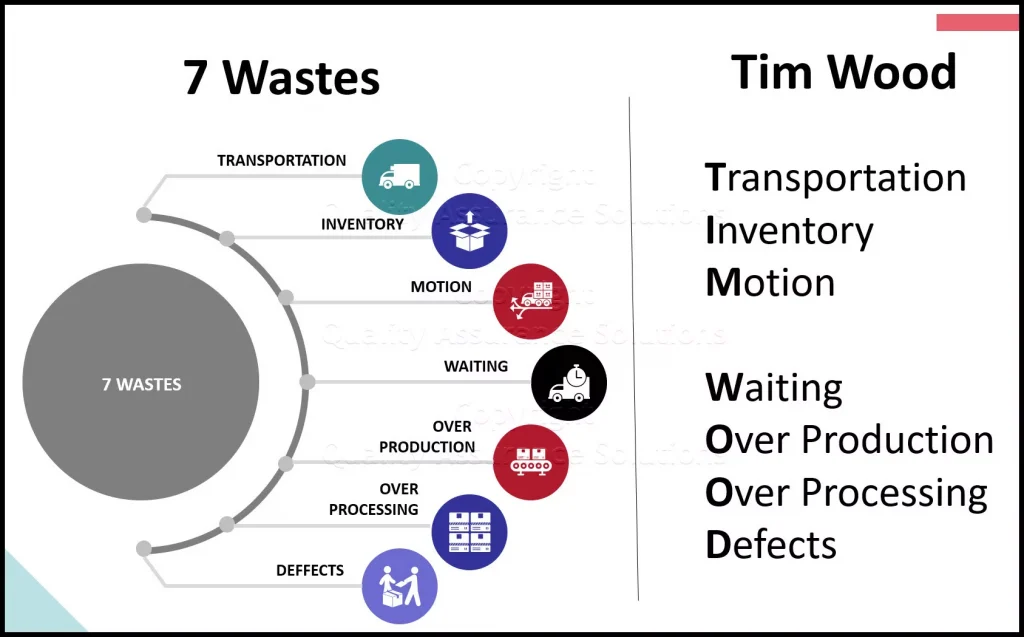

7+1 Wastes:

Applying Lean to Construction:

Construction projects are inherently complex, with multiple stakeholders, unpredictable environments, and interdependent tasks. However, Lean principles can be effectively applied to optimize site activities and contractor performance. Here’s how:

- Planning and Flow: Lean promotes early and detailed planning, breaking down projects into smaller, manageable tasks with clear dependencies. This improves workflow, reduces bottlenecks, and identifies potential delays before they occur.

- Waste Reduction: Every minute spent waiting for materials, fixing mistakes, or moving unnecessary inventory is wasted. Lean encourages continuous improvement to identify and eliminate these wastes, leading to increased efficiency and productivity.

- Collaboration: Lean fosters open communication and collaboration between all stakeholders, from designers to contractors to subcontractors. This promotes problem-solving, reduces rework, and ensures everyone is working towards the same goal.

Benefits of Lean in Construction:

The advantages of implementing Lean in construction are numerous:

- Reduced project costs and improved profitability

- Faster project completion times and improved schedule adherence

- Enhanced quality and reduced defects

- Improved safety and worker satisfaction

- Increased customer satisfaction and loyalty

Getting Started with Lean:

Taking the first step towards Lean construction can seem daunting, but it doesn’t have to be. Here are some tips:

- Start small: Choose a specific area, like material procurement or waste management, and pilot a Lean initiative there.

- Educate your team: Invest in training and workshops to introduce Lean principles and tools to your staff.

- Seek external support: Consider collaborating with Lean consultants or joining industry groups for guidance and resources.

- Measure and celebrate: Track your progress and celebrate successes to keep motivation high.

My Personal Advice:

- Focus on the “why” before the “how.” Understand the benefits of Lean and how they align with your company’s goals.

- Don’t expect perfection. Lean is a continuous improvement journey, not a destination.

- Embrace change and adapt. Lean requires a shift in mindset, so be open to new ideas and approaches.

- Be patient. Implementing Lean takes time and effort, but the long-term rewards are significant.

By embracing Lean principles, construction companies can build not just structures, but a culture of efficiency, collaboration, and continuous improvement. So, take the first step today and start building smarter with Lean Construction!

Remember: This is just a starting point. You can personalize and expand on this post by adding specific examples, case studies, or even your own experiences with Lean construction.